By addressing common pain points such as raw material quality, dimensional accuracy, and product durability, this rigorous inspection protocol ensures buyers receive wire mesh products that are reliable and tailored to their needs

+86 186 3111 8601

Production Equipment

ANPING COUNTY JINJUE HARDWARE WIRE MESH CO.LTD operates multiple product manufacturing lines. Our main weaving equipment includes Dornier looms made in Germany, multi-arm robots specialized for metal processing, and locally made Chinese looms upgraded with intelligent technology. Our production lines have an annual capacity exceeding 2 million square meters, producing gray and black mesh rolls up to 500 feet in length.

Products Display

ANPING COUNTY JINJUE HARDWARE WIRE MESH CO., LTD. offers an extensive range of products, encompassing up to 40 categories of metal wire mesh products. These include metal wire items, various types of wire mesh, and a wide array of nails. Looking ahead, we are committed to advancing research and development to create new product lines, continuously expanding our catalog to meet the diverse needs of our customers.

Metal wire is a linear, rod-shaped metallic material. Typically, metal wire is formed by drawing metal through holes on a mold or drawing plate, resulting in cylindrical metal wire. The specifications of the wire come in various standard sizes, represented by specification numbers or cross-sectional areas.

Quality Inspection

ANPING COUNTY JINJUE HARDWARE WIRE MESH CO.LTD is an ISO 9001:2000 certified wire mesh manufacturer with a stringent quality management system. From the preparation of raw materials, we implement standardized inspection processes to ensure material quality, establishing a robust supply system from the source. Additionally, we conduct intensive individual inspections of finished products to ensure a high qualification rate for every batch. Our ultimate goal is customer satisfaction, building a strong reputation through our premium products and exceptional service.

Detection Process

Detection Process

01

Raw-material-inspection

Each batch of incoming stainless steel wire undergoes comprehensive testing for its chemical composition, physical characteristics, and dimensional tolerances. This ensures compliance with strict quality benchmarks and avoids failures during production.

02

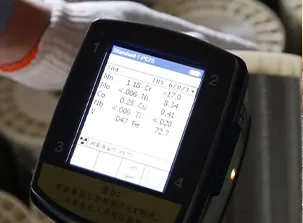

Carbon and Sulfur Analysis

Specialized tests are conducted to measure carbon and sulfur levels in the raw materials, as deviations from standard specifications can significantly affect product durability and corrosion resistance.

03

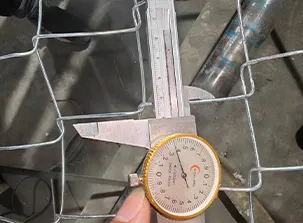

Wire Diameter Precision

The raw wires proceed to the drawing process, where precise diameter measurements are maintained. Production halts when the wire reaches the exact size needed for weaving, preventing waste and ensuring uniformity.

04

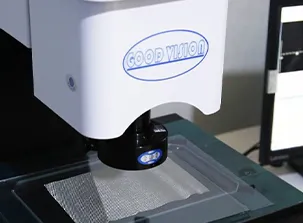

In-Process Monitoring

Before full-scale weaving begins, technicians fine-tune CNC weaving machines. Quality control personnel inspect the flatness and alignment during test runs, ensuring flawless operation and adherence to client specifications.

05

Mesh Opening Inspection

After trial production, samples are extracted and subjected to precision tests for opening size and uniformity using advanced equipment. This step guarantees consistency and compliance with design standards.

06

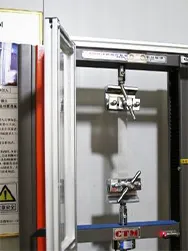

Tensile Strength Testing

Final samples are tested for tensile strength using calibrated testing machines. This ensures the wire mesh can withstand operational stress and meet durability expectations.

By addressing common pain points such as raw material quality, dimensional accuracy, and product durability, this rigorous inspection protocol ensures buyers receive wire mesh products that are reliable and tailored to their needs

Comprehensive Pre- and Post-Sales Support

Our pre-sales team guides clients in selecting the best specifications and materials for their needs, while our after-sales department offers installation assistance and addresses any post-purchase questions to ensure seamless use and long-term reliability.

View MoreLet's Talk

Shipment Display

ANPING COUNTY JINJUE HARDWARE WIRE MESH CO., LTD. boasts a fast and efficient logistics system. Once our products pass rigorous quality inspections, they are packaged according to their specific requirements. Packaging options include pallet packing, waterproof kraft paper with plastic film wrapping, carton and wooden box combinations, and customized packaging solutions upon request. After the packaging is counted and confirmed, the goods are promptly loaded and transported to Tianjin Port at the fastest speed. Our after-sales team monitors the entire shipping process to ensure that customers' products arrive safely and securely.